CRF-2 Cleanroom Fogger

The Cleanroom Fogger uses 10 ultrasonic devices to create a high volume of pure fog to visualize airflow patterns and turbulence in smoke studies of Pharma ISO suites, sterile rooms, medical rooms and semiconductor clean rooms; providing compliance to USP 797 Pharmaceutical In-situ Airflow Analysis, Airflow Recovery Tests in ISO 14644-3, Visualization Tests for ISO 14644-3 Annex B7, NSF 49 for Bio-Safety Cabinets and Semi-Standards Cleanroom Guidelines.

The Cleanroom Fogger, CRF-2, is used in smoke studies and often referred to as a smoke generator, which is used to visualize airflow patterns and turbulence in clean rooms and pharmaceutical ISO 3, ISO 5, ISO 7 and ISO 9 suites. The CRF-2 will provide instant on/off operation as an airflow visualizer for smoke studies to monitor patterns and turbulence in controlled clean room areas.

PDF-Dokument [303.7 KB]

AP-35 Cleanroom Ultrapure Fogger

A cleanroom ultrapure fogger uses liquid nitrogen and Deionized Water or WFI water to create an adjustable 2 to 5 cubic meters of ultrapure fog per minute with 533 ml of fog density per minute during a 75 minute operating cycle. The AP35 Ultrapure Fogger complies with USP 797 and ISO 14644-3 supporting visual airflow requirements and 3D airflow modeling to describe airflow patterns, direction, turbulence, dead zones and velocity in clean rooms, ISO suites, sterile rooms and medical rooms. No other competitive ultrapure fogger is capable of this fog volume, yet the AP35 costs nearly the same as competitive LN2 foggers. No contamination is created and no clean up of any kind is required after visualizing the airflow

AP35, Ultrapure Cleanroom Fogger: 2-5 Cubic Meters / Minute for 75 minutes operation, 533 ml per minute of Fog Density

The AP352 Ultrapure Fogger supports your 3D video and visual fog requirements by putting out a highly dense ultrapure fog, exceeding competitive ultrapure foggers by over 200% in fog density, 2X more visual airflow distance and nearly 2X more fog operating time. The AP35 is a work horse to satisfy airflow visualization needs in pharmaceutical ISO suites and semiconductor clean rooms.

PDF-Dokument [156.6 KB]

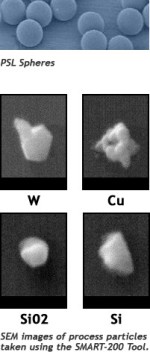

PSL Spheres and polystyrene latex beads from 20nm to 1um, NIST Traceable Size Accuracy

PSL Spheres are excellent for use with any application that requires a NIST traceable size standard with a very narrow peak standard deviation. These PSL Size

Standards are highly uniform polystyrene spheres calibrated within nanometers with NIST traceable methodology. One nanometer is 0.001 µm or 10 Angstroms. SiO2 Process particles in the 5nm and 10nm

size range are ideal for the calibration of electron and atomic force microscopes. Polystyrene latex beads are used to produce PSL Wafer Standards to calibrate KLA-Tencor SP1, KLA-Tencor SP2,

KLA-Tencor SP3, as well as Hitachi wafer inspection systems, SSIS. PSL Spheres are also used to create aerosol size standards for calibration of size response of laser particle counters and

condensation particle counters. Size calibration or wafer inspection systems, also referred to as SSIS or Surface Scanning Inspection Systems is a major requirement in the semiconductor industry.

polystyrene latex beads and PSL spheres are also used in laser light scattering studies and colloidal systems research. The 20 nm to 900 nm range of spheres is convenient to support clinical studies

for checking the sizes of bacteria, viruses, ribosome and sub-cellular components.

PDF-Dokument [253.1 KB]

PSL Spheres 1um– 60um, NIST Traceable Size Accuracy

PSL Spheres are excellent for use with any application that requires calibration of a size response curve using NIST traceable, size standards with narrow

standard deviation of the size peak. The mean size diameter of these PSL spheres are calibrated with NIST traceable microscopy methods. The size distribution and uniformity are measured by electrical

resistance analysis or optical microscopy. Polystyrene latex spheres range from 1 µm to 160 µm and are made from polystyrene (PSL). PSL Spheres are used instead of irregularly shaped particles to

minimize the laser response of analytical instruments that are sensitive to particle shape. Products from 1 to 160 µm are packaged as aqueous suspensions in 15 mL dropper-tipped bottles.

Concentration is maintained at 1.05 grams per cm cubed. Each bottle of PSL spheres contains a Certificate of Calibration and Traceability to NIST which includes a description of the calibration

method and its uncertainty, and a table of chemical and physical properties. A Material Safety Data Sheet (MSDS) with handling and disposal instructions is also available. Packages are lot-numbered

for convenient technical service and support after the sale.

PDF-Dokument [350.4 KB]